The Fuselage Team of this semester’s IP Plane Team also made progress over the last few weeks.

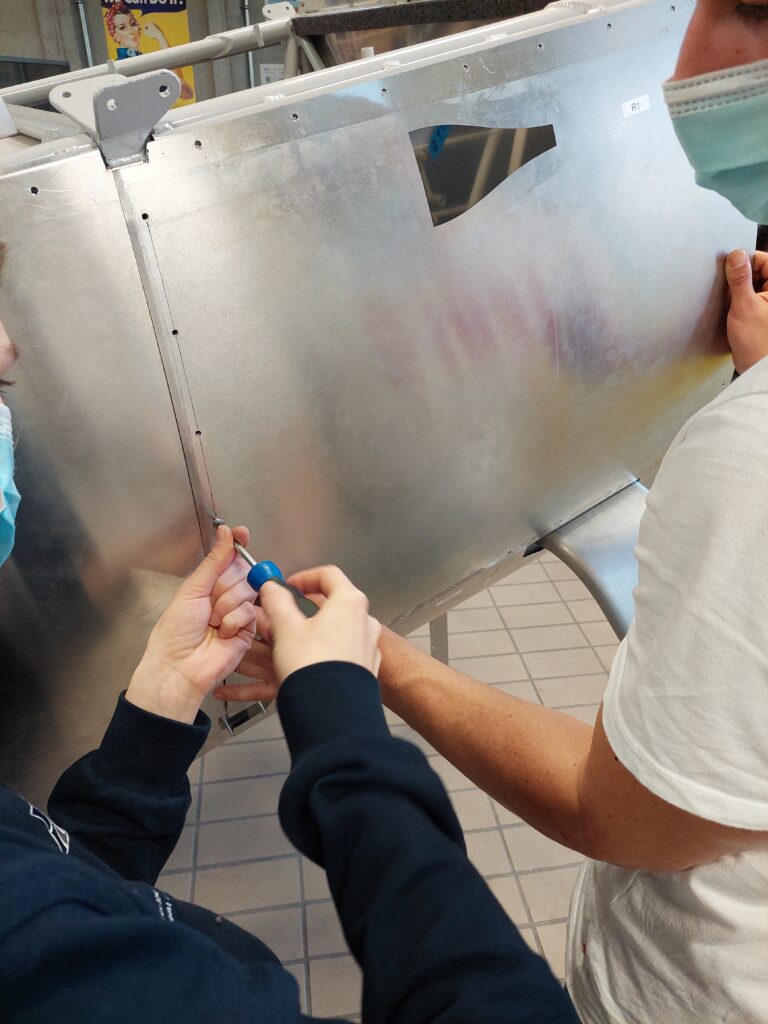

They started by drilling the holes in the sheet metal and attached the Nut Plates to properly connect the sheet metal to the frame.

For the pilot’s well-being in the canopy, it was necessary to refit it to the closing mechanism. After that work was done, the canopy could be closed properly.

The avionic panel was bent into its correct form so all instruments can later be placed on it, according to the construction plan.

The Pitts Model 12 is a stunt aircraft, therefore the Fuselage Team worked on the installation of the Flop Tubes. With them, it is always ensured that the engine is supplied with fuel, even in the middle of a looping.

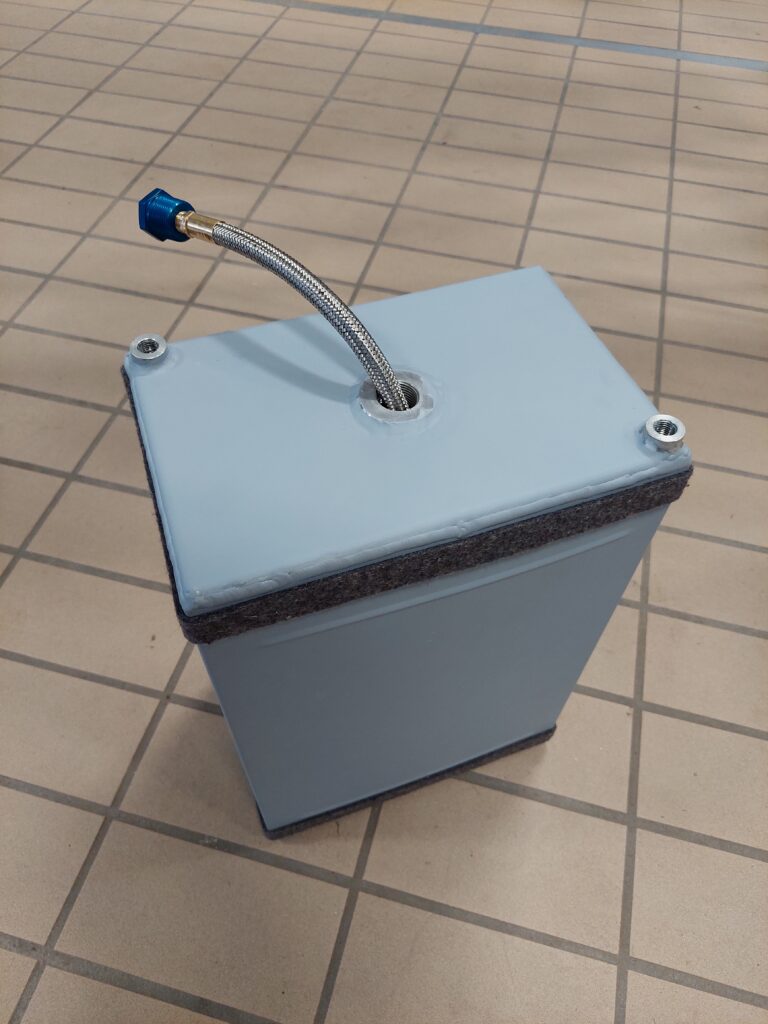

The channel for the brake pipes was 3D printed with the help of one of our professors for a safe landing procedure.

For the time coming it is to install the tanks that were coated this semester. Also, the metal sheets need to be reworked, as it is necessary to remove all corrosion from the surface.