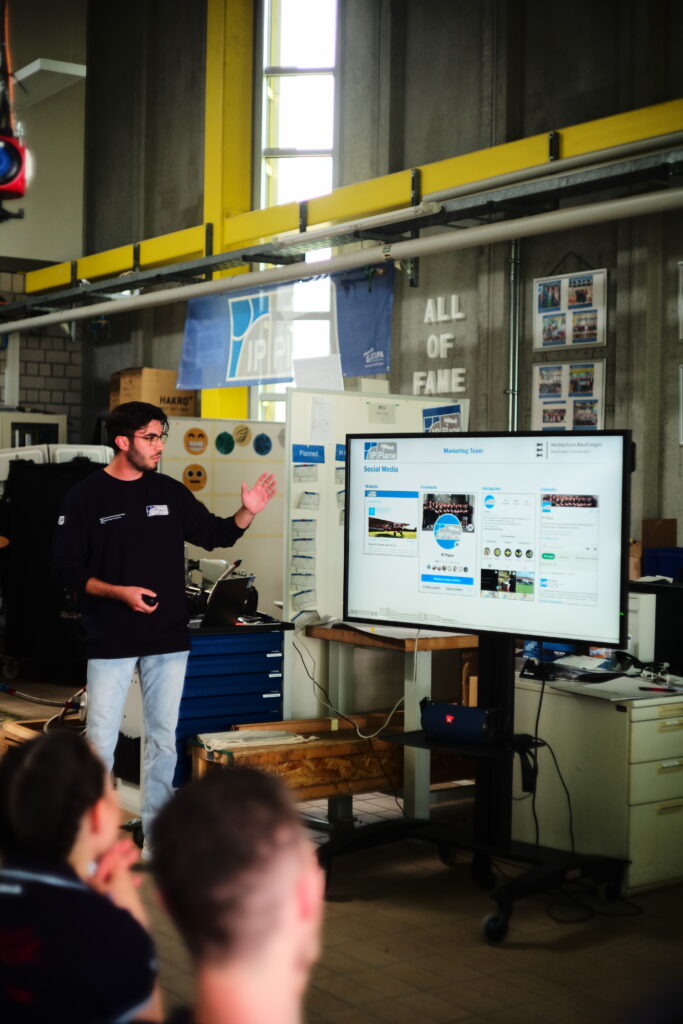

On 29/6/2022, the IP Plane team of the summer semester 2022 had their third milestone. At the M3 an overall review of the project was given. The Project Office, Marketing Team, and all three Construction Teams presented the total project progress and goals achieved to the project sponsors Jochen Brune and Markus Wachter.

Fuselage

The Fuselage team completed many of their work packages. They installed most of the panels with the rivet gun. The holes were drilled, sunk, deburred, and painted. The team realized as they wanted to screw the panels on, that the drilled holes did not align with the threading of the nutplates. Therefore, the holes in the rails needed to be sunk bigger and needed to be repainted. Unfortunately, during the semester, the retainer screw of the rivet gun broke, consequently the team had to pause this work package for a while. However, even after continuing some of the holes were still not aligned properly.

Another work package of the team was the installation of the three tanks – header, main and smoke tank. The first step of the team was to design a plywood plate as a basis for the header tank. This was then installed in the plane in front of the pilot’s seat. On top of this the main tank was attached. Unfortunately, on top of the main tank a previous team had attached a too thick felt, so the straps that held it in place were too short. This was solved by removing the old felt and attaching a new one with a thinner layer. After this the main tank was installed successfully.

Furthermore, one of the teams work packages was to install the brake lines. As soon as the team started this work package, they realized the brake system was more complex than anticipated and that it would take more time than originally planned to order the correct parts. The first part of the order arrived two weeks before the end of the construction phase and the last part still is due to arrive. Part of this work package was also the brake line fairing which protects the aluminium brake lines from external influences. The team wanted to 3D print this with the means of the university. The first prototype did not fit, however the second one did. The team then order the right material and the brake line fairing will be ready to print in a few weeks’ time. This work package was given the status „partially done“. Nonetheless, the team set up an instruction for the installation of the whole brake system, the brake cylinder, and the brake pads on both sides. Therefore, the next semester will be able to fully complete this work package.

Last, the team did a few repairs. The corrosion on the turtle deck was sealed and in cooperation with the paint shop the removal of this was coordinated. Open tasks here are to check if the canopy fits over the panel after their installation and the replacement of the bushings which guides the bolts when the canopy is being closed. The team is still waiting for the delivery of the delrin rods for the bushings.

Wing

The goal of the Wing Team was to complete 6 work packages. The first work package of the two fully completed workpackages„attachment of the butt plates to the spars“, was to bolt the metal plates to the ribs, at the connection of the fuselage. Attached to these plates were drag wire lugs which will later be used for the mounting of the drag wires. The second work package was to level the helling with an accuracy, of <.2°. Throughout the semester this was rechecked several times by the team to ensure no deviations and a high quality.

The work package “glue ribs onto spars“ was partially completed. In this work package, all the compression ribs were glued. These ribs will act as anchor points for drag wires which will be attached later in the project. In the work package „install wooden blocks for drag wires on spars“ most of the blocks were already glued on. These blocks are located on the inside and outside of the spars. Due to delivery problems with an epoxy glue, this work package could only be partially completed.

The work package “drill drag wire holes“ was not completed as a lot of preparatory work needed to be done by the team. The team designed a drill jig from a square steel tubing which will be manufactured over the summer in the university. Therefore, all the preparation work has been completed and the next semester can finish it. “Install drag wires“ could not be completed as it builds on the work step drill drag wire holes from the previous package.

The goal of the Wing Team was to complete 6 work packages. The first work package of the two fully completed workpackages„attachment of the butt plates to the spars“, was to bolt the metal plates to the ribs, at the connection of the fuselage. Attached to these plates were drag wire lugs which will later be used for the mounting of the drag wires. The second work package was to level the helling with an accuracy, of <.2°. Throughout the semester this was rechecked several times by the team to ensure no deviations and a high quality.

The work package “glue ribs onto spars“ was partially completed. In this work package, all the compression ribs were glued. These ribs will act as anchor points for drag wires which will be attached later in the project. In the work package „install wooden blocks for drag wires on spars“ most of the blocks were already glued on. These blocks are located on the inside and outside of the spars. Due to delivery problems with an epoxy glue, this work package could only be partially completed.

The work package “drill drag wire holes“ was not completed as a lot of preparatory work needed to be done by the team. The team designed a drill jig from a square steel tubing which will be manufactured over the summer in the university. Therefore, all the preparation work has been completed and the next semester can finish it. “Install drag wires“ could not be completed as it builds on the work step drill drag wire holes from the previous package.

Engine

The motor of the Pitts Model 12 is Russian 9-cylinder star motor from Vedeneyev. The motor model MP14F has 412 PS and has 3 external systems – the oil system, the fuel system and the Kimball Air Starter System.

Compared to the two other construction teams no manual was available on how to install the 3 systems to the motor.Therefore, the Engine Teams overarching objective was to create a manual for the motor. This handbook contains among other things detailed technical drawings, hints, and instructions on how to install the motor, maintenance instructions, starting instructions and many other important topics. The next semester should be able to install the 3 systems and fit the motor.

One of the biggest obstacles to overcome was to find accurate technical information for the installation of the specific systems. Mostly no sufficient information could be found online, therefore, the team did literature research and asked university staff members. Furthermore, they visited and asked a construction team from Donzdorf who also built a Pitts Model 12 with a Vedeneyev motor. The team manged to resolve most of their questions in this meeting.

With the M3, this semesters part of the project is officially completed. The next step is the handover (M4) of the project to the next IP Plane Team of the winter semester 2022/2023.

The IP Plane Team SS22 looks back with great pride on this semester and thus on a very successful project. All teams worked on their goals with the utmost commitment and each developed individual, applied project management methods and contributed to the success. The entire team would also like to thank the sponsors for their constant support in every situation and for giving us the opportunity to work on such a project.

We look forward to seeing the IP Plane fly one day and wish the future IP Plane Team WS22/23 much success and all the best, you can always count on our support!