As the summer semester of 2025 comes to a close, the IP Plane team can look back with pride on a period defined by vision, teamwork, and meaningful progress.

Together, we tackled open questions from previous phases and integrated new technological advances. Every challenge we faced was met with creativity, determination, professionality and every milestone reached brings us closer to our shared goal of soaring through the air.

The achievements of this semester are not just technical – they are a testament to what we can accomplish as a united, motivated team. As we celebrate the successful completion of the summer semester, we look forward with excitement and confidence to the next phase of the IP Plane project.

Avionic

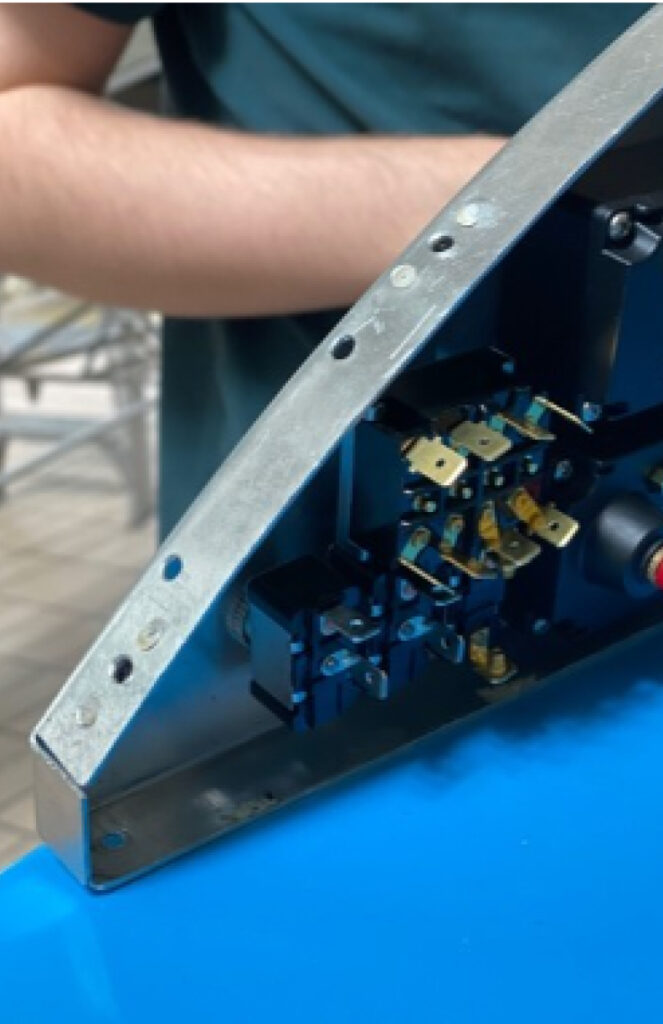

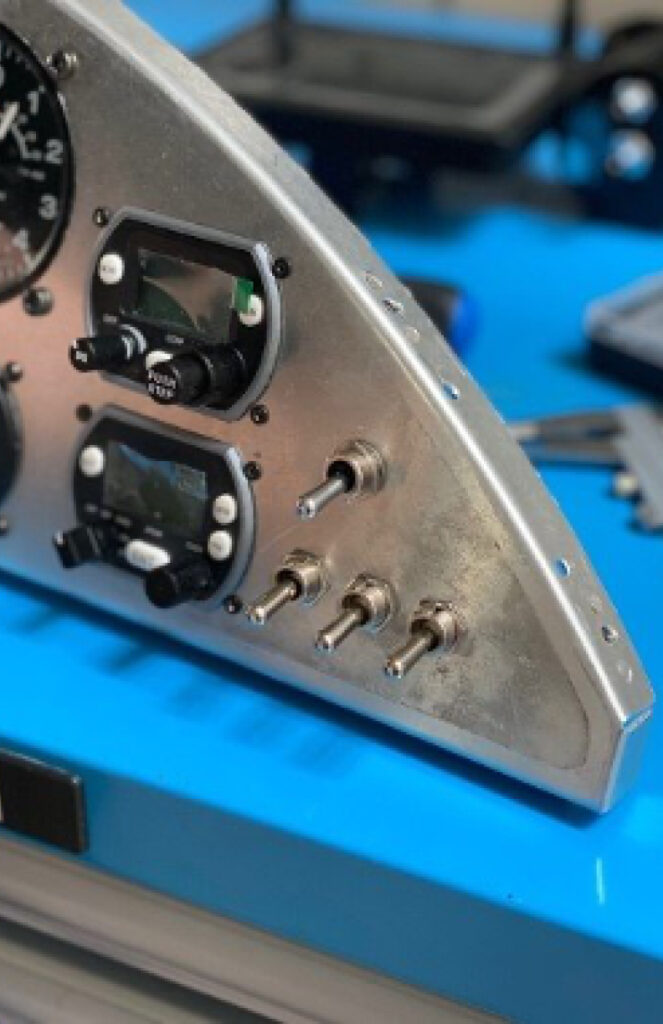

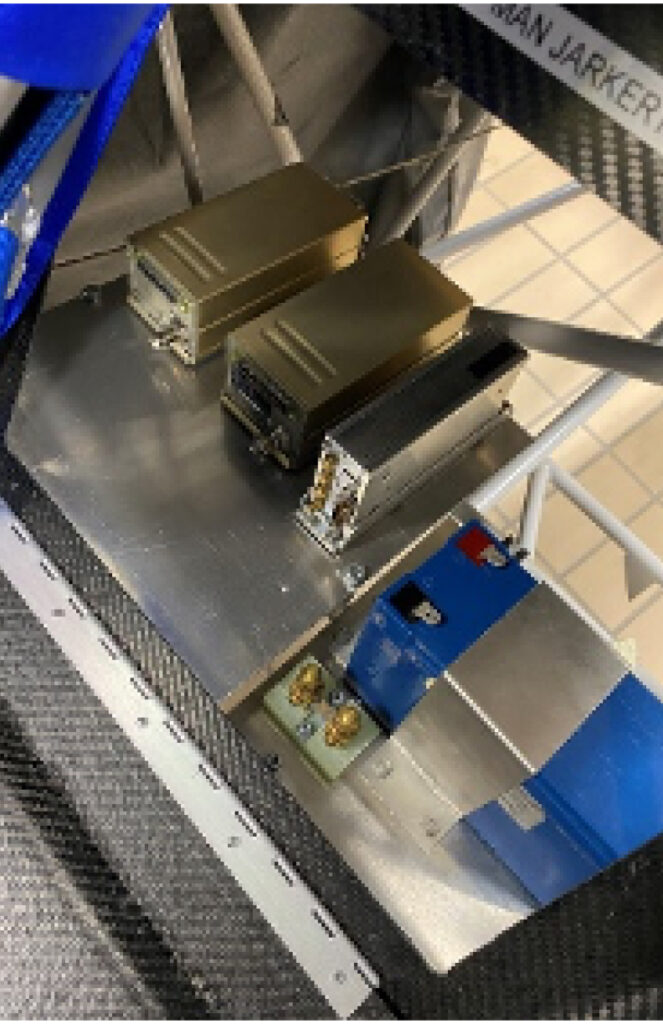

This semester focused on clarifying outstanding issues from previous planning phases, integrating new developments into our system, and implementing initial preparatory measures. A major highlight was the successful installation of the avionics switch, which now reliably protects the sensitive onboard electronics from voltage spikes during engine start. After integrating the switch into the circuit diagram, it was installed in the pilot panel, completing the panel’s assembly.

Additionally, two USB interfaces – one each for the pilot and copilot – were installed. These enable communication with the EFIS (Electronic Flight Instrument System) and allow for easy uploading of maps and flight data.

To optimize cable management, the pilot panel was temporarily mounted in the cockpit. This allowed us to identify optimal cable routes and create a dedicated conduit for all wiring into the pilot panel – an important step towards safe and clean cabling.

Engine

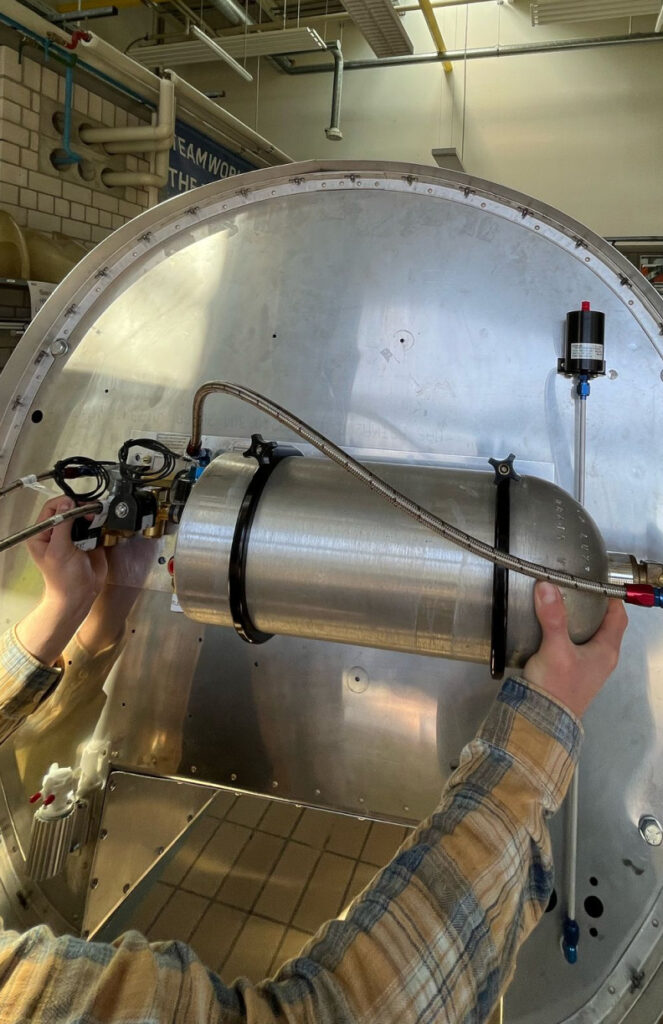

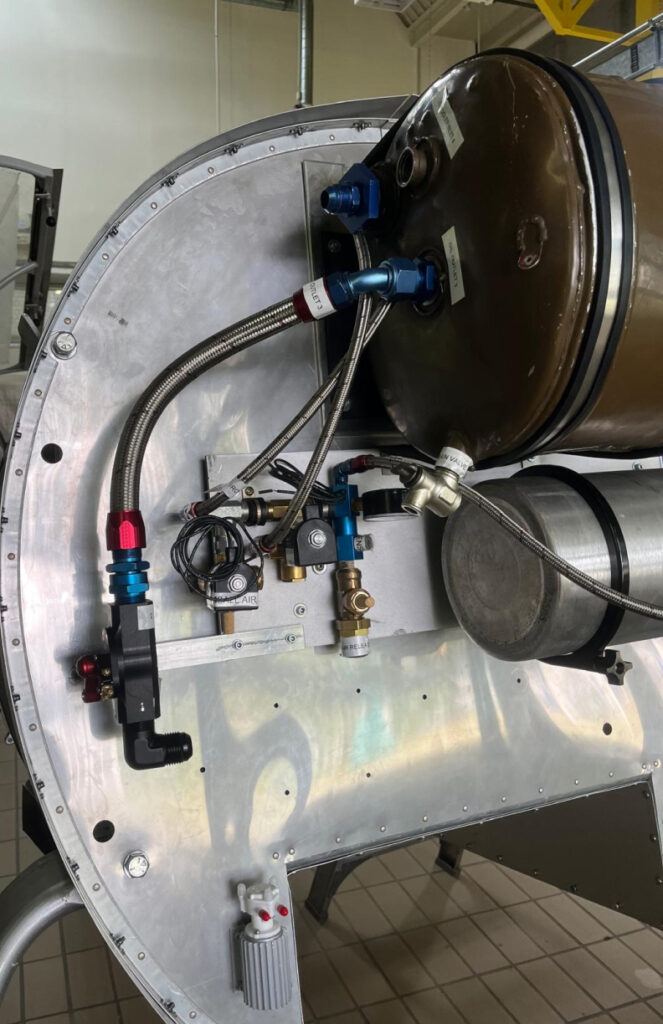

The most important and successful achievement for our team this semester was, without a doubt, the installation of the engine on the aircraft. This moment was the culmination of months of planning, coordination, and hard work, and the anticipation leading up to it was immense. The entire team dedicated themselves to preparing every detail, ensuring that when the time came, the process would go smoothly and safely.

Mounting the engine marked a significant milestone for the project, representing not only technical progress but also a boost in motivation and team spirit. Seeing the engine finally attached to the airframe was a powerful reminder of how far we have come and how much we can accomplish when we work together towards a common goal. This achievement has propelled the Engine Team forward and brought us to the threshold of our next big objective: the first engine test run.

As we look ahead, our focus now shifts to a few remaining but crucial tasks. The installation of the exhaust system, the careful routing of hoses behind the firewall, and the setup of the smoke system are all essential steps that will ensure the engine operates safely and efficiently. Each of these tasks requires precision and teamwork, and we are fully committed to completing them to the highest standard.

Once these steps are accomplished, nothing will stand in the way of a successful test run.

Wing

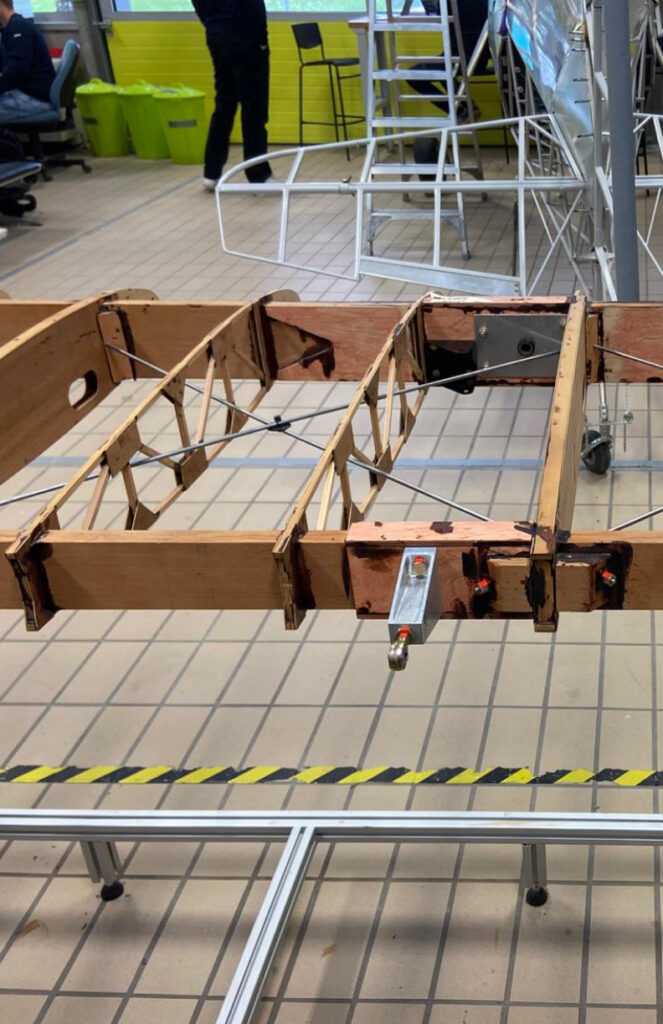

This semester marked a turning point for the Wing Team, as the steady groundwork from previous semesters has now translated into several tangible achievements. The careful preparation and planning invested earlier have laid a solid foundation, allowing us to celebrate significant visible progress this term. All ribs have now been glued into their final positions – a major milestone, as they had previously been loosely fitted between the spars. The ailerons, which had already been mounted in earlier phases, have now been properly aligned and are fully operational following the installation of the control mechanism. Additionally, the walkway was installed, representing one of the final woodworking steps on the lower wings. With this, the majority of the woodwork is nearing completion.

Looking ahead, a few important steps remain to bring the lower wings to completion. The airspeed indicator (pitot tube) still needs to be installed, and the ribs must be trimmed at the rear to match the length of the ailerons. The installation of the aileron control mechanism and a few minor finishing touches will round off the work on the lower wings. Once these tasks are finished, the wings will be ready for fabric covering and final assembly.

This semester’s progress has brought us closer to completing the wings. The visible results of our efforts have energized us, and we are excited to carry this momentum forward into the next phase of the project.

Motivation and Next Steps

With the successful completion of this semester, we look forward to the challenges ahead and are confident that the IP Plane team, we will continue to achieve great things. Thank you to everyone participating this semester whether as a team member or a fan.

“The entire team worked with impressive passion and innovation throughout the summer semester 2025. Every single contribution brings us closer to take-off, and we are proud of our shared achievements. We hope that the next semester can carry our momentum and use it to exceed their own expectations!”

Aaron Beigel, Project Manager Summer Semester 2025